As a result of this exciting merger, we are redirecting you to www.amcor.com where you can explore the expanded range of packaging solutions and innovative products that we now offer. For more information about this acquisition and to read the official press release, please visit: Read the Press Release

We look forward to continuing to serve our valued customers with enhanced capabilities and a broader portfolio of packaging solutions. Thank you for your ongoing support.

is a mono-oriented polythene (PE) film that helps to

convert conventional laminates of mixed materials into mono

material structures, enabling 100% recyclability.

is a mono-oriented polythene (PE) film that helps to

convert conventional laminates of mixed materials into mono

material structures, enabling 100% recyclability.Globally, companies are working to convert their non-recyclable – multi material packaging structure into simple packaging structure with mono material, that can be 100 % recyclable.

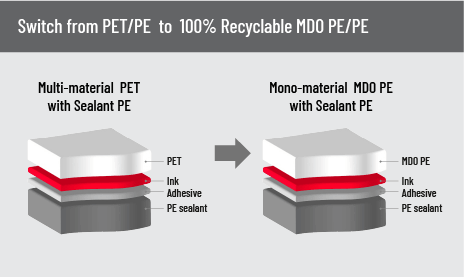

Thanks to extensive research, MDO PE films can match transparency & stiffness of PET films, thereby converting PET/PE structure to recyclable PE/PE structure. MDO PE Film will be used to replace PET film, thereby making laminate 100 % recyclable while retaining same gloss & stiffness.

Recyclable films are seen as a major alternate for Sustainable Packaging & is being accepted by major Global FMCG companies.

Phoenix Flexibles will have an advantage as early entrant into MDO PE film offering through investment into Inline MDO PE Film Line from Hosokawa Alpine, Germany.

There is huge interest from major FMCG brands for ‘SUSTAINABLE PACKAGING OPTIONS’

Delivers greater stiffness & higher optical properties, which can replace PET/BOPP/BOPA film as printing layer.

Technical Data SheetProvides excellent clarity & stiffness. Possible downgauging while replacing traditional Sealant PE films.

Technical Data SheetMetallized MDO-PE film for barrier properties against gases, moisture & aroma.

Technical Data Sheet