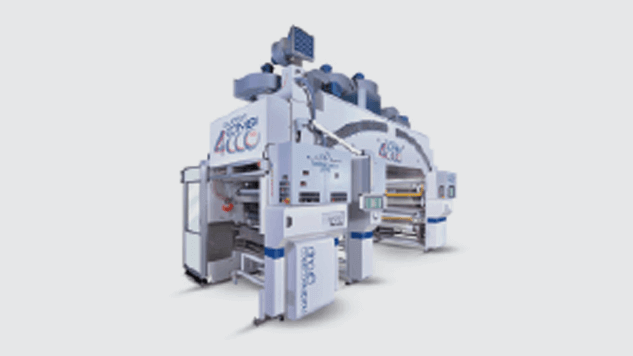

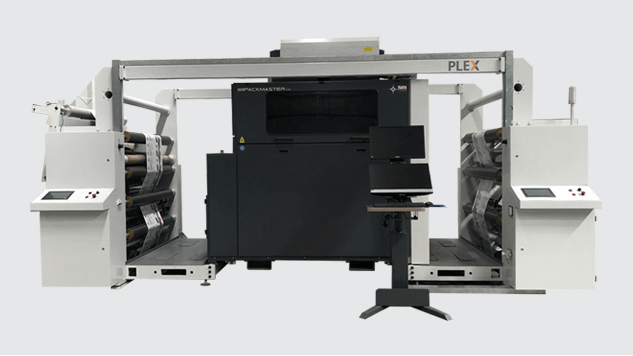

Gravure Priniting Machine: 3 Nos.

- Line Speed: 350 Mtrs/Min & with 1250 mm width

- Turn Bar for Reverse Printing & Coating Capability

- 100 % Defect Detection System from AVT – Israel with Inline Barcode Verifier with

Print flow-Work flow modules

- ESA (Electronic Static Print Assistant System) from Enulec – Germany to get

maximum dot gain during printing

- Centralized Ink Viscosity Control System from New Celio – Switzerland with Ink

Temperature Control Module & Solvent Mixing Module

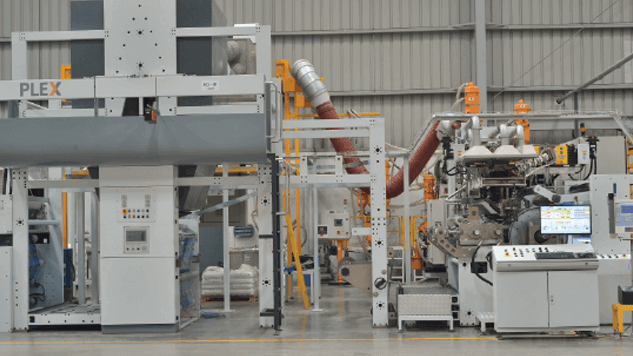

Extrusion Coating & Lamination

- Line Speed: 350 Mtrs/Min with 1300 mm width

- Turrets for Primary & Secondary Unwinder & Re winder

- Auto T Die from Cloeren USA with 3 Layer Feed block

- Auto Thickness Gauging System from NDC USA

- Co ex Extruders with Bimetallic Screw & Barrels from Xalloy, USA

- Servo Driven Technology from SIEMENS – Germany

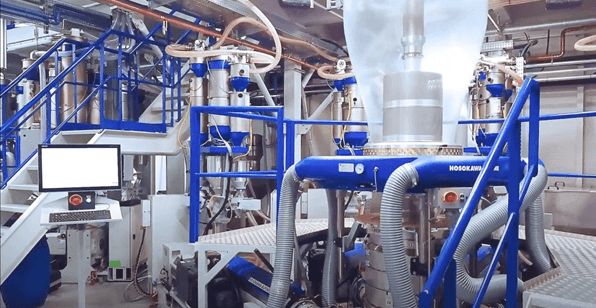

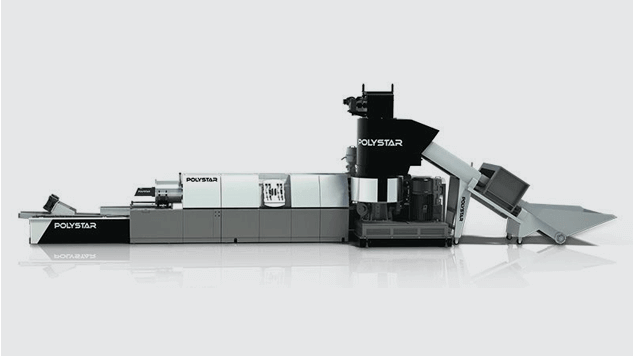

5 Layer Blown Film Line: 2 Nos.

- 5 Layer Configuration.

- Width – 2700 mm. Out Put – 800 Kgs/Hour

- 4 Component Gravimetric Dosing System from Plast control, Germany

- Fully Automatic Winder with Taper Tension Arrangement

- Corona Treater from AFS – Germany

Pouching Capabilities: 7 Nos.

- Three Side & Centre Sealed Pouches with & without Zipper

- Stand-Up Pouches with & without Zipper

- Shape Pouches with & without Spout

- Spout Pouches

- Laser Scored Pouches for Easy Opening

- Coffee Pouches with Degassing Valve

- High Speed operation with 240 strokes/min

- Equipped with Thomson Die Cut unit for Shaped pouch

- Capabilities of up to 4 lane pouch making for Three-Side-Seal pouches & 2 lane

Stand-Up pouch making can produce up to 480 pouches/minute

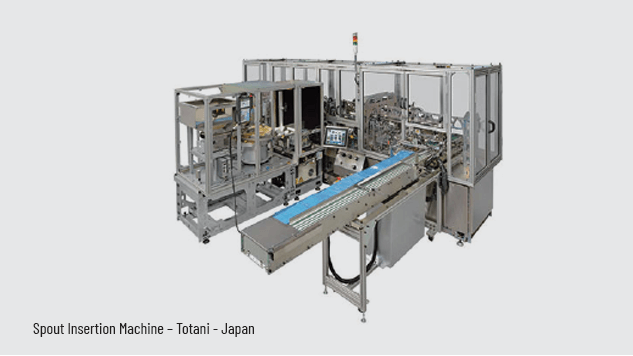

Spouting Capabilities

- Provides Leak Free Sealing of spouts with neat & clean sealing

- Allows the insertion of spouts into laminated pouches at a rate of 60 spouts per

minute

- Can work with any shape of pouch

- Fully Automatic Operation with Angle Cutting of Pouch as an option

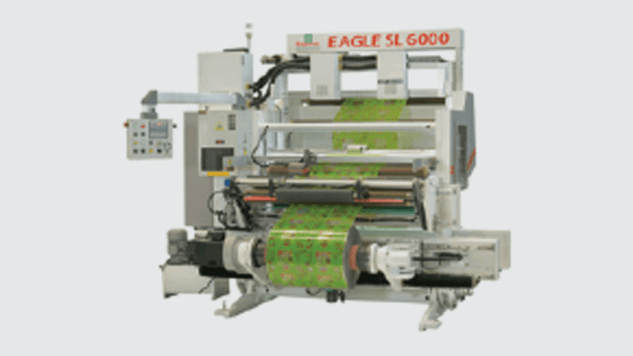

Laser Scoring & Perforation

- Can be used for laser scoring, laser cutting & laser micro perforation

- High Speed Operation through 2 Nos. 300 W laser source

- Some of the applications :

- Easy Tear for Premade Pouches

- Breathable Packaging through micro perforation

- Window Packaging, etc.