As a result of this exciting merger, we are redirecting you to www.amcor.com where you can explore the expanded range of packaging solutions and innovative products that we now offer. For more information about this acquisition and to read the official press release, please visit: Read the Press Release

We look forward to continuing to serve our valued customers with enhanced capabilities and a broader portfolio of packaging solutions. Thank you for your ongoing support.

Working towards

converting complex

multi-material stuctures

to mono-material structures

Consumers today, especially Millennial consumers, are willing to pay more for products from companies with sustainable values and practice. This trend will grow in years to come. More & more companies will choose sustainable options going forward.

Majority of Brand owners have committed to using recyclable, biodegradable or compostable packaging by 2025 in place of difficult-to-recycle multi-layer plastic packaging.

Sustainable packaging is our priority. Phoenix Flexibles will offer sustainable packaging under “Econix brand”.

Flexible Packaging can be classified into three categories based on its source & its environmental impact.

Conventional hydrocarbon-based packaging material with different polymers is a single-use product. Recycling of such films is not possible & usually, end-of-life will be land-fil.

Phoenix Flexibles is focussing circular economy with Recyclable Packaging. Recyclability can be achieved by using Mono-Material flexible packaging that uses one polymer only for different layers - most often polyethene & polypropylene.

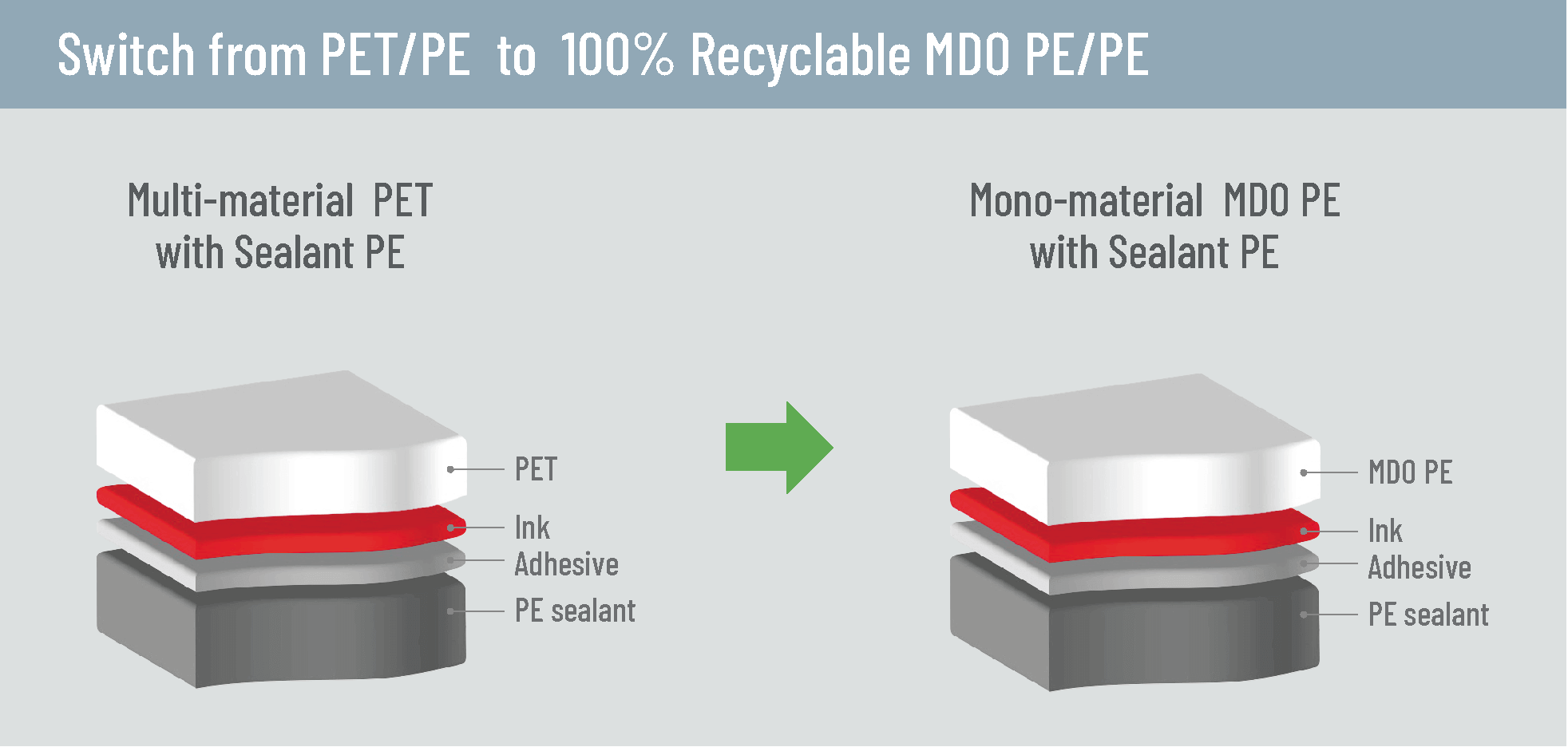

Globally, companies are working to convert their non-recyclable – multi material packaging structure into simple packaging structure with mono material, that can be 100 % recyclable.

Thanks to extensive research, MDO PE films can match transparency & stiffness of PET films, thereby converting PET/PE structure to recyclable PE/PE structure. MDO PE FILMS will be used to replace PET film, thereby making laminate 100 % recyclable while retaining same gloss & stiffness.

Recyclable films are seen as a major alternate for Sustainable Packaging & is being accepted by major Global FMCG companies.

Phoenix Flexibles will have an advantage as early entrant into MDO PE film offering through investment into Inline MDO PE FILMS Line from Hosokawa Alpine, Germany.

RP 100% Recyclable & Mono-material Films

RP 100% Recyclable & Mono-material FilmsEconix RP is 100% recyclable printed & laminated roll stock films & pre-made pouches.

Econix RP is Mono-Material flexible packaging that uses one polymer only for different layers - most often polyethene & polypropylene.

Multi-material flexible packaging is made of two or more materials laminated together by adhesive. Due to the multi-material structure, recycling of such films is not possible & usually, end-of-life will be land-fil. MDO PE films can match the transparency & stiffness of PET films, thereby converting PET/PE structure to recyclable PE/PE structure.

Econix RP roll stock & pre-made pouches are 100% recyclable while retaining almost the same gloss & stiffness. Econix RP is offered with either all polyethene or polypropylene material.

There is enormous interest from major FMCG brands for ‘Sustainable Packaging Options’. Econix RP offers the benefits of recycling and provides decisive competitive advantages: